Co-ordinate measuring machines, precision sensors and accessories for fast, accurate acquisition of component dimensions and surface data. Find out how Renishaw CMM products can help optimise your manufacturing.

The world’s leading range of CMM measurement systems

For more than 50 years, Renishaw has delivered innovations that have been milestones in industrial metrology. From the original touch-trigger probe and motorised indexing head, to repeatable stylus changing and modular scanning systems, Renishaw sensors for co-ordinate measuring machines (CMMs) are an industry standard on all makes of CMM.

The 5-axis measurement product range represents the biggest step-change in measurement capability ever introduced, delivering unprecedented speed and flexibility.

Our latest range of AGILITY® CMMs delivers award-winning REVO® 5-axis measurement technology to the shop floor and the lab. Designed for flexibility and production performance, these 5-axis CMM systems deliver higher productivity in automotive, aerospace and other demanding precision manufacturing industries.

AGILITY high-performance CMMs deliver REVO 5-axis measurement speed, accuracy and flexibility to the shop floor and the lab with Renishaw’s manufacturing quality and innovative technology.

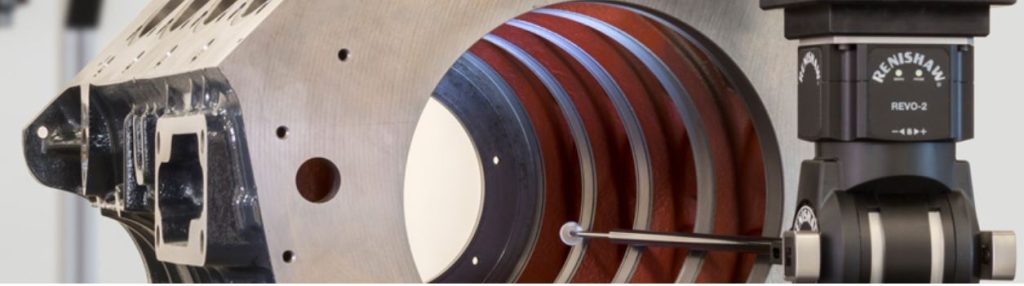

REVO 5-axis multi-sensor measurement systems deliver high-accuracy, high-speed scanning, non-contact and surface finish inspection on a single CMM

The world’s leading range of touch-trigger and scanning measurement systems, racks and accessories for all types of co-ordinate measuring machines

Transform your measurement performance with our innovative metrology systems. A one-stop solution for optimised measurement supplied and supported by Renishaw.

What is 5-axis CMM measurement?

Based on advanced head, sensor and control technology, Renishaw’s 5-axis measurement technology delivers unprecedented measuring speed and flexibility, whilst avoiding the speed versus accuracy compromises inherent in conventional techniques. It boosts measurement throughput, minimises lead times and gives manufacturers a more comprehensive appreciation of the quality of their products.

Unlike systems based around indexing heads or fixed probes, 5-axis motion enables the stylus to follow a continuous path around complex components without having to leave the surface to index the head. Controller algorithms that synchronise CMM and head motion produce an optimal tip path and minimise CMM dynamic errors.

Speed, accuracy, and flexibility

With its extensive range of probes, the REVO 5-axis CMM measurement system provides unmatched flexibility. The system provides automatic switching between tactile scanning, touch-trigger, ultrasonic, vision and surface finish measurement.

By integrating multiple sensors on the same CMM reference frame, the REVO system enables manufacturers to increase productivity significantly and can eliminate the need for other dedicated inspection equipment.

This single-machine solution overcomes the delays and risks of damage associated with transferring parts across multiple inspection locations. Reducing part handling and part movement minimises scrap and optimises shop floor layout, leading to lower energy consumption.

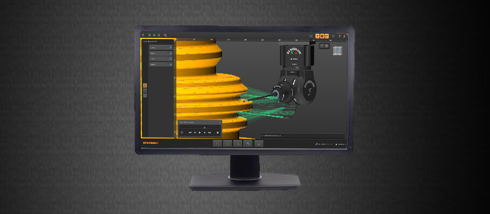

MODUS™ metrology software

Renishaw’s metrology software is a powerful platform for 5-axis measurement. It allows for offline development of native DMIS programs, extracting geometry and tolerance data from CAD. The software includes certified feature measurement, construction, and part alignment algorithms. Programs can be created offline with probe path verification and simulation, reducing downtime on the CMM.

The MODUS software suite ensures compatibility with future sensor and controller advancements from Renishaw, including the 5-axis measurement product range, which offers enhanced speed and flexibility without compromising accuracy.