Ergo- The indexable cutting tools with ER taper-shank.

Optimize the rigidity. Excellent repeatability, saving set-up time.

• The ergo system include milling cutter, spot drill, chamfering tool, engraving tool, deburring tool, chamfer mill and center drill.

• Perfectly suitable for driven tools and spindles with ER interface of CNC turning centers and swiss type automatic lathes such as Star, Citizen, Tsugami, Doosan, Tornos, INDEX, EMAG and so on.

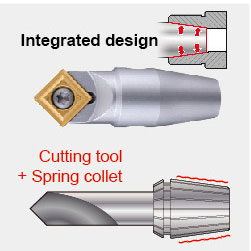

An integrated ER taper- shank cutter, eliminate assembly tolerance.

A clamping force from the 3 parts including Ergo nut, high strength pin and ER taper when Ergo nut drives the pin to Ergo holder into ER taper.

Optimize the rigidity. Increase tool life.

- An integrated ER taper-shank cutter, eliminate assembly tolerance. 100% contact with spindle taper cone. • Reliable machining resulted a better run-out accuracy, eliminate vibration, cutting noise and chatter.

Easy and simple assembly.

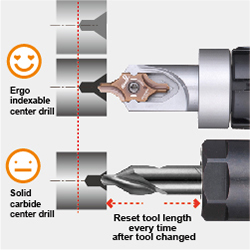

- A simple Ergo cutter has minimal assemble parts, changing tool takes just few seconds. • Thanks to ER taper, the repeatability of assemble tolerance is ±0.1mm ( 0.0039”) while changing same tool length Ergo holder.

Quick change, saving huge machine downtime

- The simplest way to get tools on the machine. • Fixed tool length of Ergo system. • No need to reset tool length while changine tools.

Excellent repeatability, saving set-up time.

- Not only a drill, but an end mill too.

• Indexable insert provides the greatest benefit of saving tool changing time and tool length setting time. • The drilling depth is constant after change the insert or cutting edge.

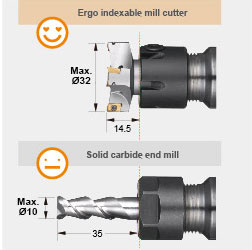

Dimension is not limited by the ER16 collet clamping range.

- Ergo ER16 covers milling cutte range from 10 to 32mm. • More efficiency and the possibilities to machine bigger parts. • The shorter tool length, the better run-out accuracy.