Bowers Group’s precision measurement expertise was crucial in supporting the University of Wolverhampton Racing Team (UWR) with the manufacture of an adaptor plate. This plate converts the standard oil heat exchanger on the BMW B48 engine into an external oil cooler system, used by OEM manufacturers such as Morgan, MINI, and Toyota.

Key Points:

- Precision Measurement: Bowers Group supplied an XT3 Holematic thread gauge, aiding UWR in achieving optimal performance.

- Partnership with Morgan Motor Company:

- Engaged in building two new CX platform Plus 4 cars from road vehicles into racing cars.

- In March 2021, these were the first of their kind.

- During track tests, high engine and oil temperatures were observed, particularly in the automatic version.

- Addressing Overheating Issues:

- UWR aimed to lower oil temperatures to mitigate overheating.

- The BMW B48 engine had no off-the-shelf oil cooler conversion available at the project time.

- The team decided to cool the oil externally, rather than relying on the standard heat exchanger.

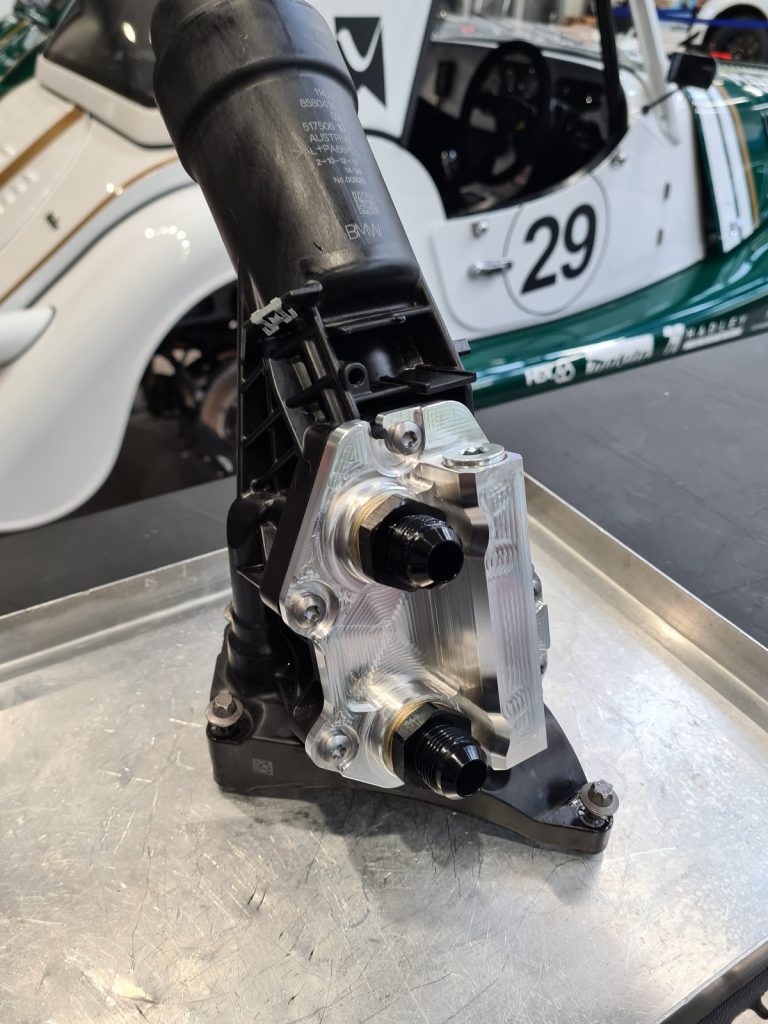

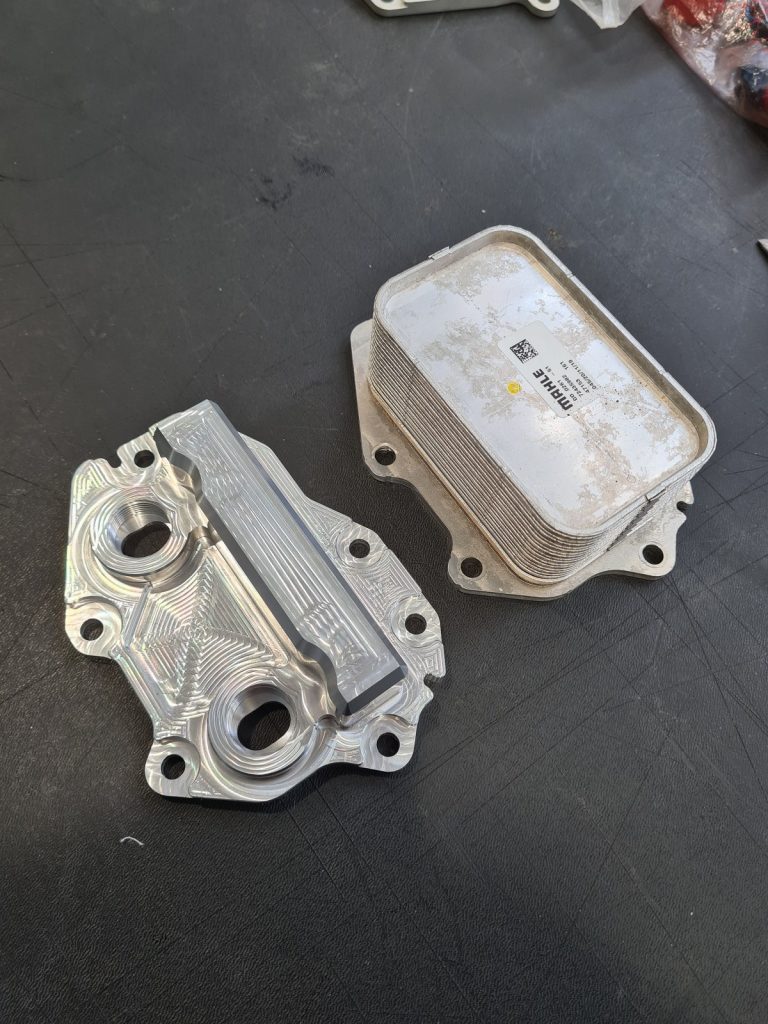

- Adaptor Plate Design:

- Designed to replace the standard heat exchanger on the oil filter housing.

- Enabled installation of an external oil cooler system, effectively lowering both oil and engine temperatures.

- Collaboration and Tooling:

- UWR sought assistance from Bowers Group, Quickgrind, and Tungaloy UK for tooling and manufacturing.

- Bowers Group promptly supplied an XT3 Holematic Thread Gauge to ensure accurate manufacturing of the adaptor plate.

- Precision Manufacturing:

- The plate acted as a fluid barrier and pathway for oil and engine coolant, necessitating precise measurements.

- The XT3 Thread Gauge ensured accurate production, matching the CAD design, and preventing crossover between oil and coolant pathways.

- Successful Implementation:

- The final fitment of the adaptor plate to the oil filter housing was successful in both workshop and track testing.

- The precision and timely support from Bowers Group were instrumental in the project’s success.

Testimonials:

Professor Amar Aggoun, Head of the School of Computer Science, Engineering and Mathematics, praised the support from Bowers Group:

“The speedy assistance from Bowers Group helped us produce a bespoke solution in manufacturing a heat exchanger replacement adaptor plate for the B48 BMW engine found in the Morgan Plus 4. The expertise and understanding of our sponsors ensured smooth manufacturing, positively impacting the whole project. We are extremely grateful for their support.”

The XT3 Thread Gauge from Bowers Group ensured precise measurements, matching the CAD design and resulting in a usable and safe build for the racing cars. This partnership highlighted the value of precision measurement in high-performance automotive engineering.