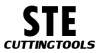

Stable grooving with unique holder design

Insert securely held to achieve excellent machined surfaces

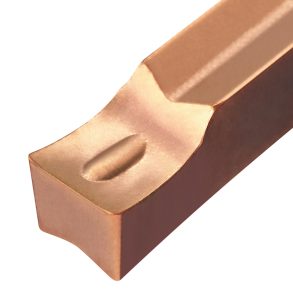

Features

- Insert widths range from .118 – .236 of an inch

- Two 3D chipbreaker styles to choose from

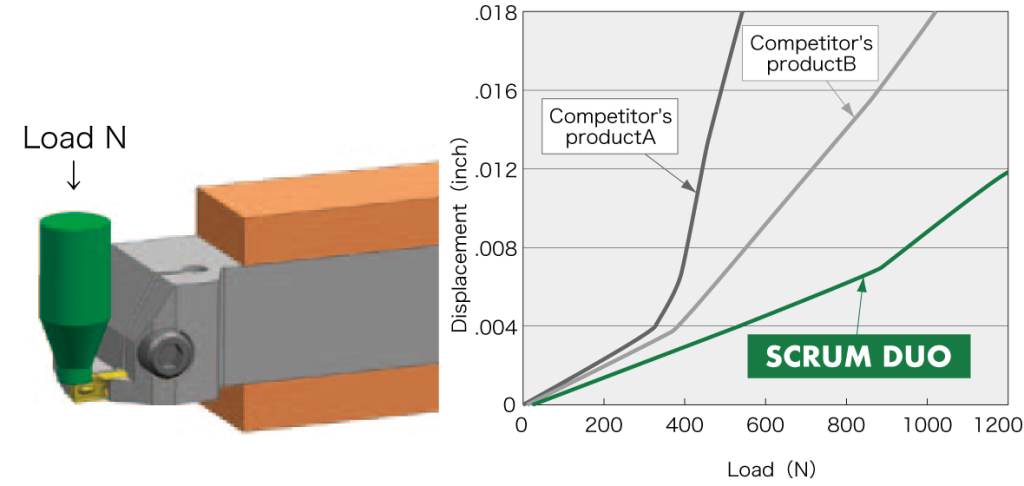

GW: Sharpness, excellent chip control, best for side turning

GV: Superior sharpness for less tool pressure to prevent chattering and results in good surface finish

Tooling application

Swiss CNC lathes

Grooving and Side turning

Cutting conditions

| Coated grade | Material | Operation type | Cutting speed (SFM) | Groove width (inch) | Grooving feed rate(IPR) | Side turning feed(IPR) ※ GW chipbreaker only |

|---|---|---|---|---|---|---|

| DM4 | Difficult-to-cut material / titanium alloy Alloy steel / carbon steel / hardened material / general purpose / high temp alloys | Grooving | 75 – 600 | .118 – .157 | .002 – .006 | .001 – .004 |

| 157 – .197 | .004 – .008 | .006 – .012 | ||||

| .197 – .236 | .006 – .014 | – |

Grooving

[ Cutting conditions ]Material : SCM415 Groove width .0197 inch 500 SFM .004 IPR .275DOC Non-step grooving WET[ Tools used ]Insert : DM4 GWPG500N04F-GW Holder : GTWPR2525M-5F10

Side turning

[ Cutting conditions ]Material : SCM415 Groove width .0197 inch 500 SFM .004 IPR .039DOC Non-step grooving WET[ Tools used ]Insert : DM4 GWPG500N04F-GW Holder : GTWPR2525M-5F10

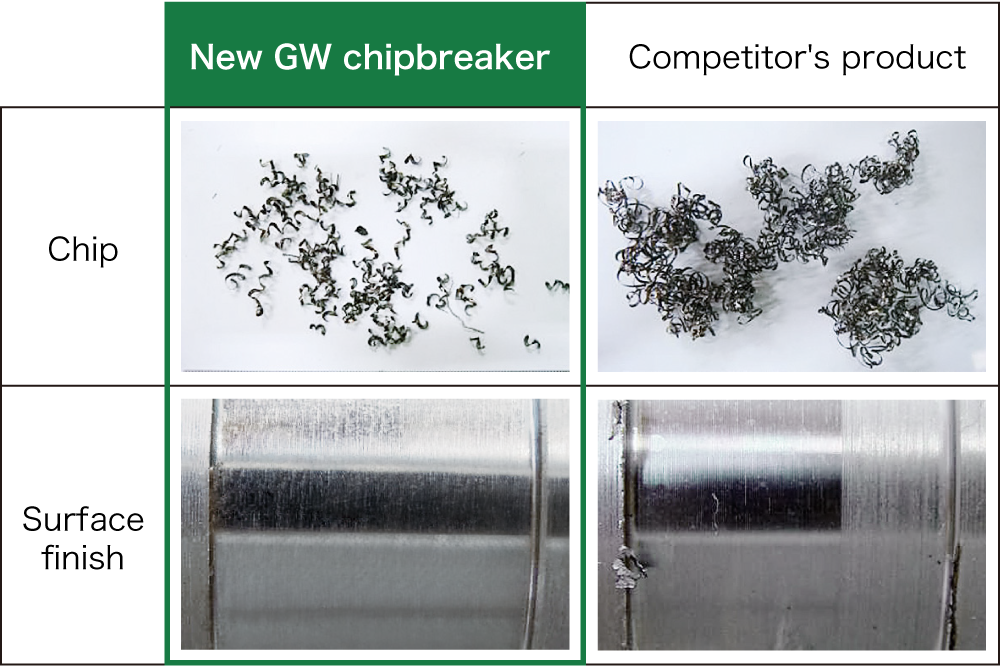

Two chipbreaker styles combined with our tough DM4 carbide grade for long tool life and quality surface finishes

GW chipbreakerA versatile design with edge sharpness and chip control features.

Multi-functional for grooving and side turning

GV chipbreakerFeatures superior sharpness with high rake face Ideal for applications requiring low tool pressure

Chip comparison (grooving)

Tool pressure comparison (grooving)