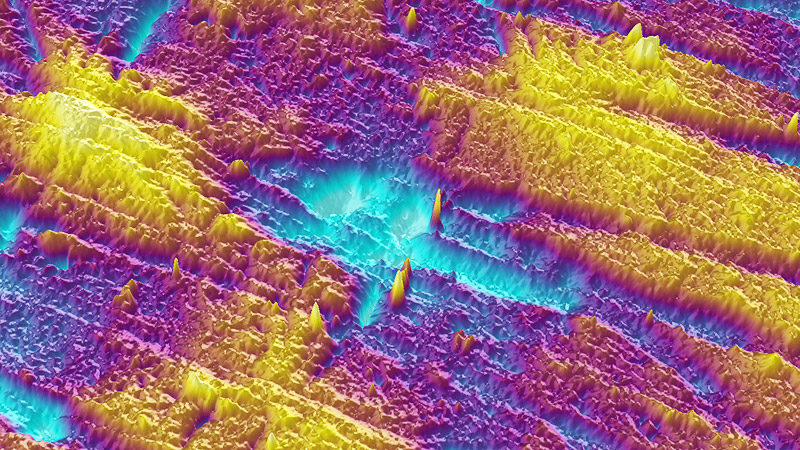

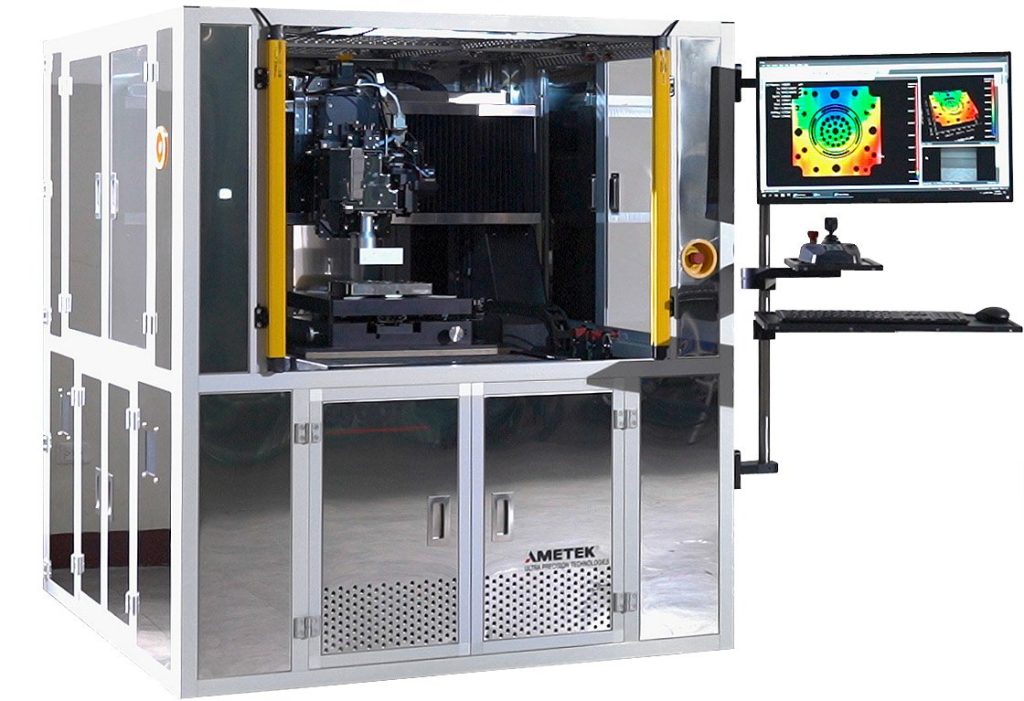

The NewView™ 9000 3D optical surface profiler provides powerful versatility in non-contact optical surface profiling. With the system, it is easy and fast to measure a wide range of surface types, including smooth, rough, flat, sloped, and stepped. All measurements are nondestructive, fast, and require no sample preparation.

At the core of the system is ZYGO’s Coherence Scanning Interferometry (CSI) technology which delivers sub-nanometer precision at all magnifications, and measures a wider range of surfaces faster and more precisely than other commercially-available technologies, thus optimizing your return on investment.

Performance, Value, and Versatility

Flexibility is the hallmark of ZYGO’s NewView products. The NewView 9000 profiler offers exceptional value with applications as varied as flatness, roughness and waviness, thin films, step heights and more.

MORE INFO

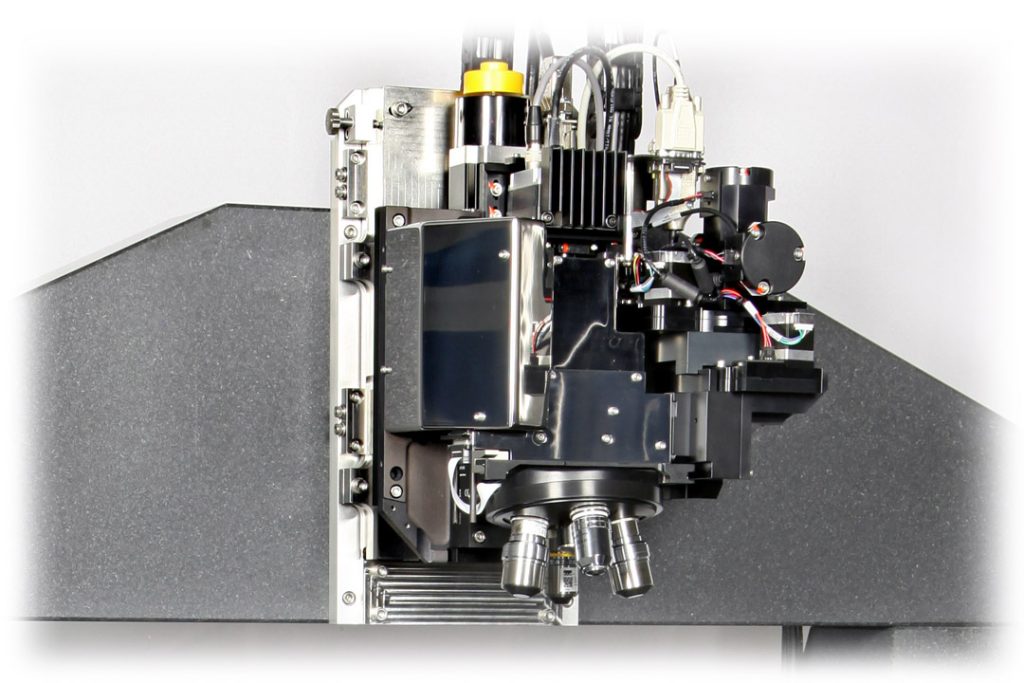

All NewView 9000 profilers are equipped with a triple-zoom turret which can be populated with discrete zoom optics tailor made for the system. Sample staging configurations range from completely manual to fully automated with encoded travel.

Regardless of your configuration, all NewView 9000 systems offer high-accuracy measurements, ease of use, and fast measurements, all at an attractive price point that make it the ideal choice for versatility and value in 3D optical profilers.

Some of the differentiated features targeted at making users’ metrology better, faster, and more reliable:

- Large-area 1.9 MP sensor with high sensitivity lets you see more in a single measurement

- High-speed measurements take only seconds for improved productivity and process control

- Automated part focus and setup minimizes operator variability and training while reducing the time to data

- Gage-capable performance through exceptional precision and repeatability for the most demanding production applications.

- Vibration robust metrology with SureScan technology and available built-in isolation enables high quality metrology even in vibration-prone environments

- SmartPSI™ technology for ultra-fast profiling of ultra-smooth surfaces

- 2D and 3D correlation provides confidence in your measurements with results that comply to ISO 25178 and ISO 4287 standards.

- Mx™ software for instrument control, analysis, and measurement automation

Flexible Configurations

The NewView 9000 profiler features an open work area, with clear lines of sight, to help make measurement setups and changeovers simple and quick. Systems can be equipped with a variety of sample staging that range from fully manual X/Y and tilt stages, to fully automated stages with 150 mm of travel and 4 degrees of tilt. With the integrated isolation system and compact size, it is well suited for benchtop installations; using the optional stand and workstation make an ideal production-style system.

The NewView 9000 profiler features an open work area, with clear lines of sight, to help make measurement setups and changeovers simple and quick. Systems can be equipped with a variety of sample staging that range from fully manual X/Y and tilt stages, to fully automated stages with 150 mm of travel and 4 degrees of tilt. With the integrated isolation system and compact size, it is well suited for benchtop installations; using the optional stand and workstation make an ideal production-style system.

Special Configurations

Large Format Inspection

OEM Systems

Industrial Enclosure

Micro Lens Metrology

Key Features of ZYGO 3D Optical Profilers

SmartSetup™ Technology

SureScan™ Technology

Optical Profiler Objectives