NC Helix Drill – Ideal for automation production.

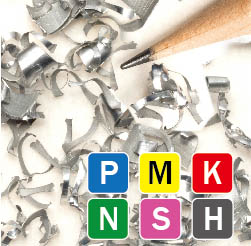

Excellent swarf removal.

For rough milling, drilling and slotting.

● The serrated cutting edge makes cutting chip short and easily to be removed.

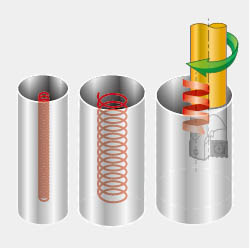

● Cut materials by Helical interpolation.

● Just one NC Helix Drill can machine different diameters and hole depths, also can performs multiple patterns, increase flexibility and occupy few tools in CNC machine.

● It is available with both external coolant supply and through tool coolant supply, making it adaptable to all Milling and CNC Machining centres.

● 3xDc ~ 8xDc drilling, screw fit type (99323 series) is recommended.

Lower spindle power consumption. Easy to cut!

Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower spindle power consumption. Work quicker, smarter and achieve better results.

Special insert geometry-exceptional swarfs control.

The serrated cutting edge makes cutting chip short and small, and easier to evacuate. Eliminate swarf and vibration problem while drilling difficult material or deeper holes. Excellent swarfs control for providing safe and rational chip removal for modern automation.

Just 4 tools for drilling Ø13mm ~ 65mm. (Ø.512”~Ø2.559”)

Cuts by helical interpolation. Each holder can machine different diameters and hole depths, possible up to 6xDc. Enlarger hole is adaptable by using 99323 internal coolant cutter.

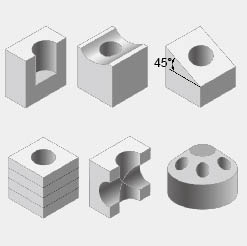

“One tool” performs multiple applications

Not only a drill, but an end mill too.

Small radius path to cut a hole or step hole, various curved cavity shapes on different materials, reduce tool number and cutting time.Small radius path to cut a hole or step hole, various curved cavity shapes on different materials, reduce tool number and cutting time.

Functions in variable conditions. It’s so easy!

Cuts by helical interpolation. Each holder can machine different diameters and hole depths, possible up to 6xDc. Enlarger hole is adaptable by using 99323 internal coolant cutter.

The insert is able to cut different materials.

For example:

- Regular Surface

- Half Hole

- Concave Surfaces

- Angled Surfaces

- Stack Drilling

- Cross Holes

- Cone Workpiece Offset Drilling