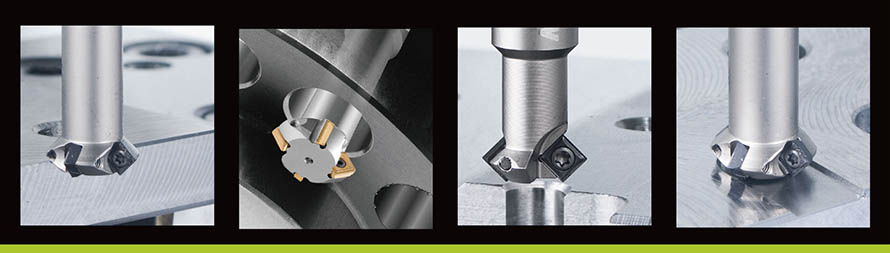

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert. It is an efficient front and back chamfering tool that is easy to use and which allows quick insert changes. The insert is a specifically designed for use in high speed machining; the multiple flutes provide for increased feed rate, optimizing performance and reducing cutting time. it runs 4 times faster in cutting speed and 10 times higher in feed rate. It is the most efficient tool you ever met.

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

• Applications: 90° counter sink and 45° chamfering. circular chamfering, contour chamfering and face milling.

Some of our most popular chamfer mill include:

Cylindrical shank:

• chamfer size: Ø6.8 ~ Ø13.2mm – 99616-C02, C04 and c06 Series:

+ Elliptical necked bar to optimize the tool strength.

• chamfer size: Ø7 ~ Ø32mm – 99616-C10 ~ 99616-C52 Series:

+ 4 inserts provide for increased feed rate, optimizing performance and reducing cutting time.

Screw fit type:

• chamfer size: Ø11 ~ Ø29mm – 99616-CM16-M05 ~ 99616-CM29-M10 Series:

+ Modular body style – Quick and easy to change system and provides chamfering flexibility.

- • [ NEW ] ER taper-shank style for chamfer mills –

ideal solution for BT30, driven tools, tapping and turning center.

+ An integrated ER taper-shank cutter, eliminate assembly tolerance.

+ Easy and simple assembly.

+ Excellent repeatability, saving set-up time.