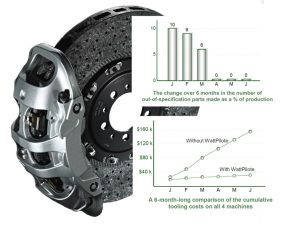

Making brake calipers on a double-spindle Vigel machining center. .This operating efficiency study was performed by the end user on 4 machining centers over a 6-month period to determine the cost reductions due to the WattPilote systems.

The study includes all machining operations that are necessary for the complete manufacture of brake calipers (milling, boring, tapping and finish boring) with Monobloc tools and complex tools with inserts mounted in expensive tool-holders.

As soon as they were set up, the WattPilote systems were able to detect any type of tool breakage. Even before the systems were used to extend tool life, this first test phase demonstrated improved production quality and limited production waste. As soon as this first phase was validated, the manufacturer made use of the tool wear monitoring function. Tools were no longer changed after making a pre-determined number of parts, but only when they were becoming worn. By intervening just before a tool breakage, WattPilote completely eliminated waste, prevented tool holder destruction, and increased the number of parts machined by each tool.

After 6 months of WattPilote use, the total savings directly related to tooling costs on these 4 machines increased by $117,500.

สอบถามเพิ่มเติมที่

บริษัท Sahatool Engineering จำกัด (สำนักงานใหญ่)

โทร : 0-2370-4937-42

อีเมล์ : sahatool@tsc-tooling.com

โทรสาร : 0-2370-4943